Ras Tek is LRQA certified ISO 9001:2015 company and is equipped to carryout repair/ maintenance of almost all makes of turbocharger.

Specialized turbocharger repair/reconditioning work is carried out under certification at state of art workshop located at Navi Mumbai.

Highly experienced turbocharger service Engineers trained at MAN, Mitsubishi, Napier and KBB are available at all locations to carry out routine overhauls and attend to breakdown on Ships and captive Power Plants.

We are authorised service partner of KBB and Mitsubishi.

Our activities Include:

- High Pressure Steam cleaning

- Turbine Blade rebuilding/repair

- Glass bead blasting

- Precision Machining

- Dynamic balancing

- Shaft Metalising

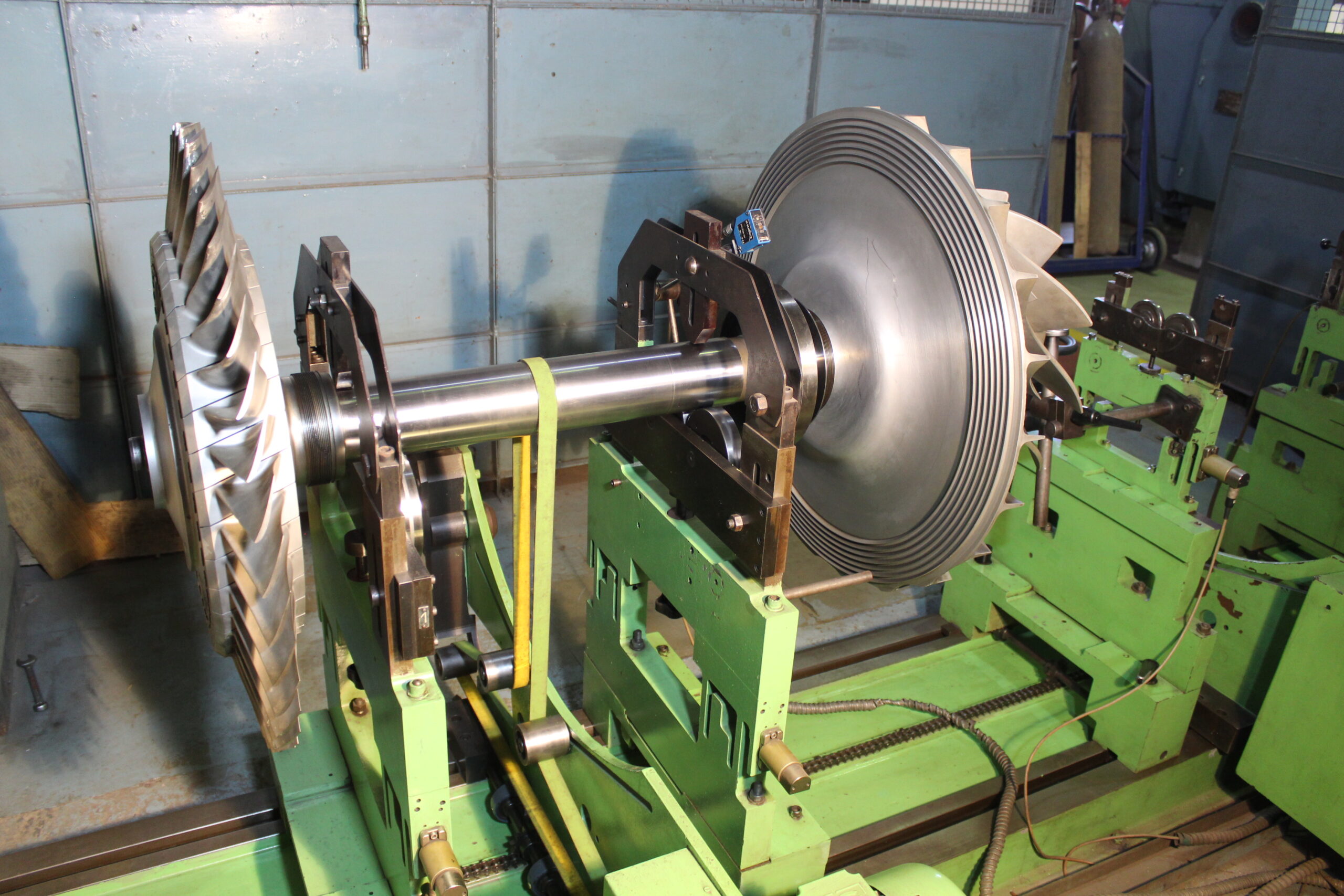

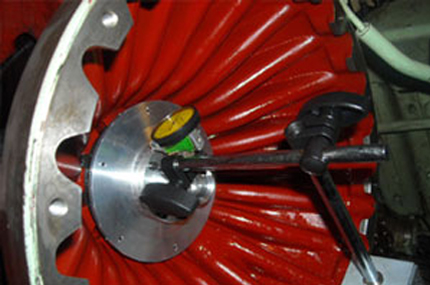

DYNAMIC BALANCING

Damaged rotor blades can cause imbalance. When this imbalance exceeds the permissible tolerance, vibrations are produced which wear the bearings and in the long-term cause major damage to the entire Turbocharger. Extensive repairs and downtime are then unavoidable.

Dynamic balancing is performed using Schenck CAB 690 H Balancing machine with H40/20 BUTL pedestals. Balancing values achieved are better than ISO 1940 & VDI 2060 standards.

BLADE REPAIRS

Damaged Blade

After Repair

Blades often get damaged in turbochargers. We mainly see four categories of blade damage.

- Damage due to foreign object

- Damage due to erosion

- Damage due to blade contact with shroud ring

- Damage due to over speed and overheating

ONBOARD OVERHAULING

NOZZLE RING REPAIR

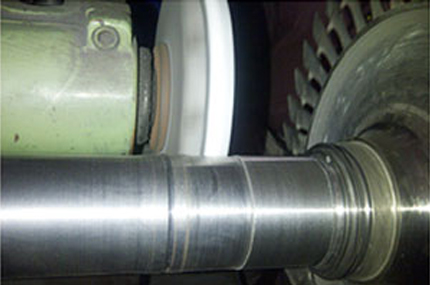

METALIZING & MACHINING

Ras Tek specializes in repairing of shaft end, seal areas, spigot and bearing journal by an ISO approved Metalizing process. This process involves three steps :

- Surface Preparation

- Thermal spray coating / Wire Arc Spray

- Machining of Metal spray/wire arc spray on shaft ends as per original dimension